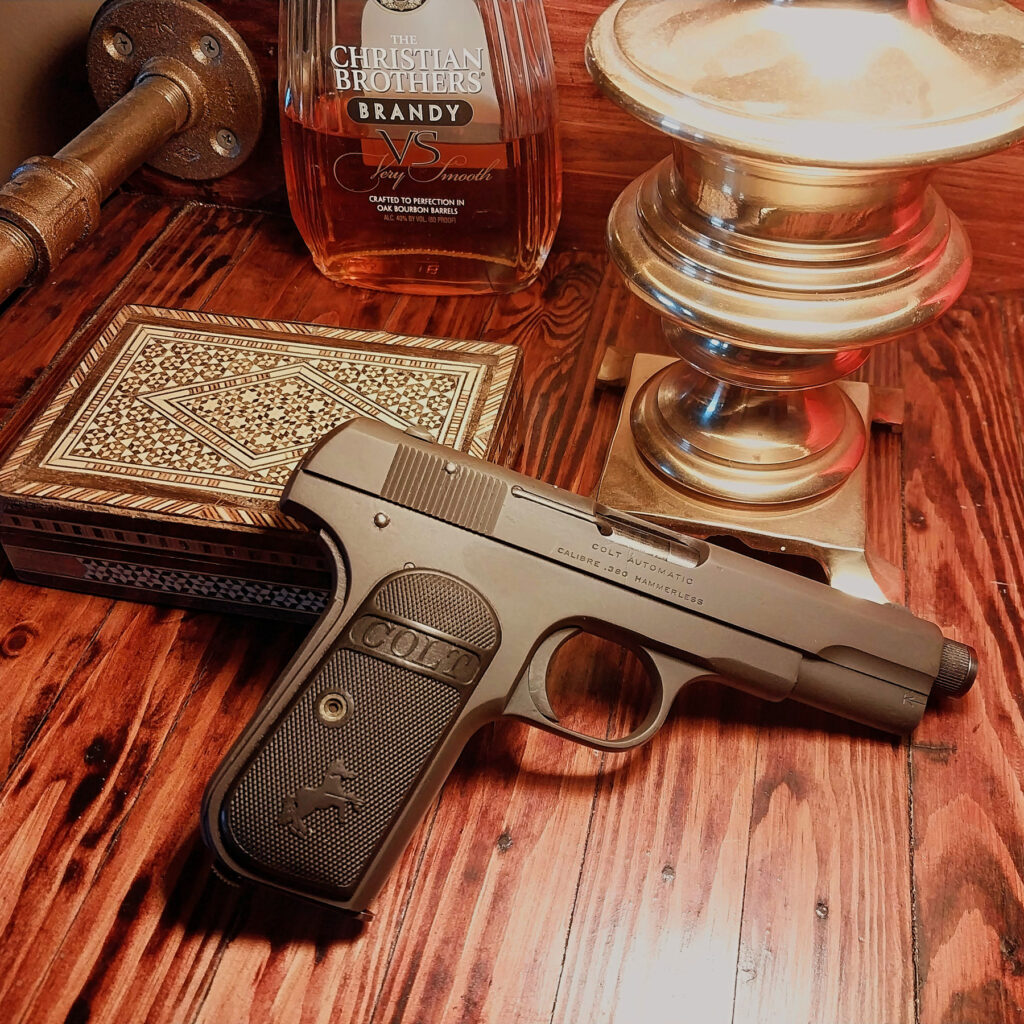

My Colt 1908 is a type III, 1920 manufacture 380 ACP pistol that wouldn’t fire safely. There was a lot that could have failed internally in the past hundred or so years but I was determined to restore it to reliable carry condition.

Cosmetically, the finish was rusted, pitted, and the bluing was long gone. One of the grips was cracked all the way through, on top of not firing when I wanted it to, and sometimes, just firing when charging the slide. It was a very dangerous piece that needed to be repaired. Not surprising for an antique handgun, over a hundred years old.

Basically, it was a POS wall hanger. Even the barrel had evidence of a squib load having been hammered out of the bore. No one wanted this ugly duck so I got it cheap. On the work bench, I stripped it down to the frame and inspected all of its parts.

The finish was toast. The rust can’t even be called a patina with all the bluing gone. This thing had a rough hundred years behind it but there was enough there to work with – the frame and slide were sound and most of the roll stamping was legible.

All the springs had to go. The disconnector was fine but the sear had sheared into two floppy pieces. The barrel was questionable too. I needed some replacement parts.

First, I got my hands on a new manufacture 380 ACP barrel. I got a threaded one, just in case I ever wanted to pay the ATF the tax for a suppressor, in the future – if I got it working safely again.

The barrel had to be fitted to the frame. That meant doing some fine filing to get the barrel lugs to properly mesh with the channels in the frame. If you’ve ever field stripped a Colt Pocket Hammerless, you know why.

The new sear was key to getting this little beast safe to carry and fire reliably. It was beautifully machined and it dropped right in like an original part.

All new springs were essential too, including the recoil spring, the main spring, the grip safety spring, firing pin spring, and the extractor spring. The original extractor was in tolerance and so was the two-piece firing pin.

I got new grips just for it to feel right in my hand.

Then I got to work, fine sanding the rust pitting flatter, without removing too much material. I just wanted to remove the edges where rust collects. It looked pretty good so far.

Then I sand blasted it in stages, using the sand blasting cabinet I just rebuilt.

Then the sides went onto the wool buffer wheel with polishing compound to remove some of the roughness.

Then with everything sand blasted or polished, everything was ready for the black oxide process.

The black oxide process goes relatively fast, like 15 minutes. It’s also not caustic like hot blue and it’s not as finicky as Parkerization. And the finished product seems to wear a lot better than Duracoat paint. From now on, I will never Duracoat, nor Cerakote a firearm ever again – I’ll only use black oxide finish.

Once the parts were the dark, dark gray I wanted, they went into the Sealing Oil to saturate the oxide surface to make it rust resistant.

A half hour later, I could start to reassemble the parts. And yes, those are chop sticks. They’re free with an order of Orange Chicken and they’re disposable.

I was happy to find the magazine was original equipment. They’re ridiculously expensive to replace. Now, a hundred year old magazine spring wasn’t going to be reliable, so I bought a new magazine spring from Wolfe Springs to get it back to factory tension.

For all the work I put into this antique, I think it came out really nice.

But fully taking apart and fully reassembling a Colt Pocket Hammerless is a real test of anyone’s patience. The slide is a cake walk but the frame is a nightmare of fine part alignment under a lot of spring tension. I had to do it twice to get the hammer and safety to align under the tension of its mainspring.

Nevertheless, it was all worth it. At the outdoor range, I was emptying the seven round 380 ACP magazine in a second. And at a hundred feet, I was actually hitting what I was aiming at. Impressive for the first pistol ever chambered for 380 ACP, more than a hundred years ago.

After range testing it, I know it’s reliable for concealed carry. It’s diminutive, thin and it literally fits into my pants pocket with nothing to snag my draw. John M. Browning designed a fantastic Pocket Hammerless pistol.

Gentlemen prefer Brownings.