This project began as a 1980s era 12 gage, pump action, Savage Model 67E hunting shotgun with a 28 inch barrel and a four cartridge capacity magazine. In the photo below, I cut the barrel down to 20 inches and added a Mossberg bead sight.

I got it at an auction for $105.00 as a beat up, broken bird gun that no one wanted. These are my favorites because few can see the potential in something that needs a little rework.

And the finish on the receiver and barrel looked like crud.

The stock had dings and chips in it. Certainly not an attractive shotgun.

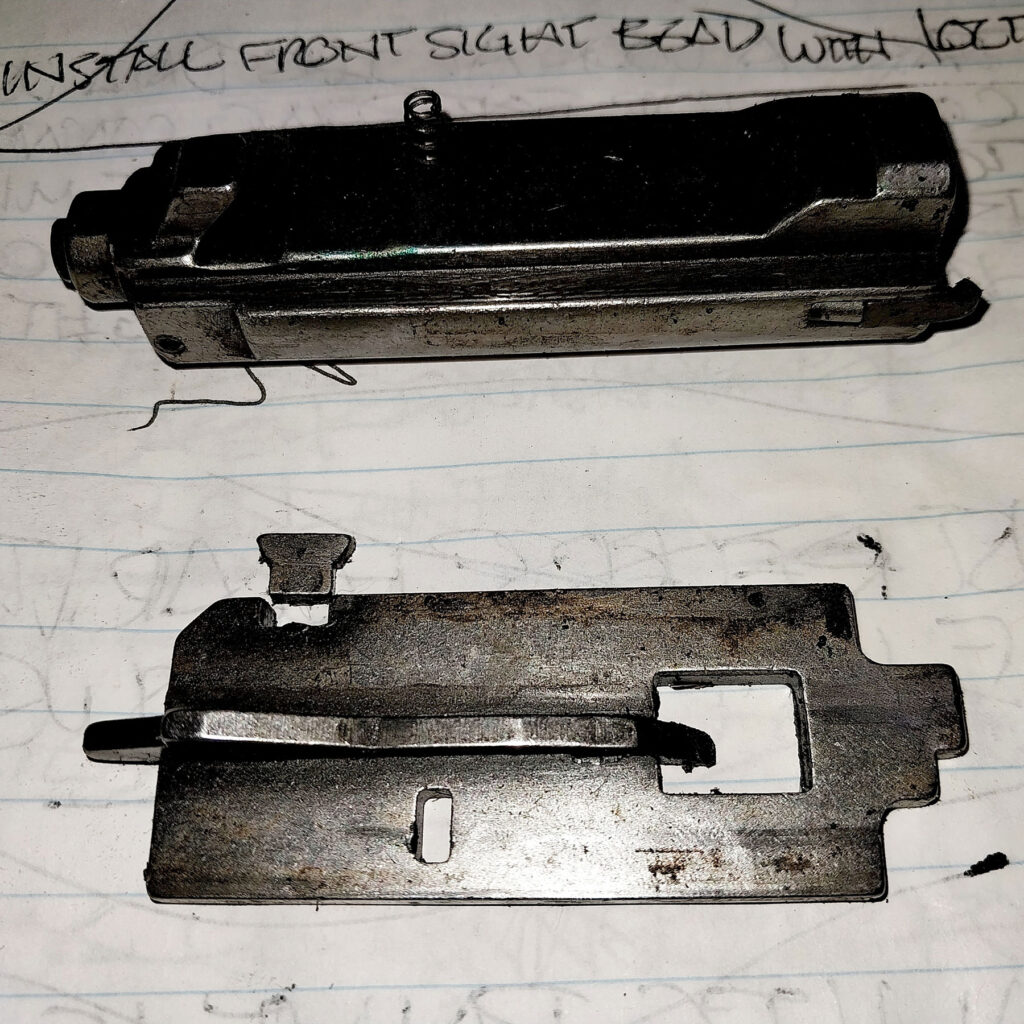

And the pump action bar lug had broken off from its weld. Who would want a shotgun like that? That’s why I got it cheap.

The first thing I did was re-weld the lug onto the bolt carrier. I didn’t even bother cleaning up the weld, which was out of the way of the receiver track so I left it alone, rather than risk weakening the weld by filing it. Yes, acute angles in a weld form stress cracks, which probably caused the original weld to fracture.

Then I tried to restore the bluing. That meant scrubbing the surface with super fine steel wool and motorcycle engine oil. It turned out really nice. Look.

Just a little polishing with steel wool and engine oil took out nearly all of the surface rust and restored the original, deep, factory blue of the steel.

Then the fire control group needed to be inspected, cleaned and preserved. Fortunately, it was fully functional. Just a spring had to be reset into its groove. It just needed to be preserved to stop further corrosion and re-lubricate it.

There was a little touch up with some cold bluing, dabbed on with a Q-tip.

Then it was time to restore the wood furniture. The fore end (pump handle) was still perfect, so I left it alone beyond rubbing it down with alcohol but the stock needed to be stripped, lightly sanded and have the dents steamed out with a clothes iron.

Then the stock was ready to be stained. I just gave it one base coat to saturate the grain, then another coat of stain to even out the underlying machine oil stains that naturally seep down from the receiver when stored vertically. It happens all the time.

Here is where I changed up the design by trying to replace the four shell capacity magazine tube with the Savage Model 69 magazine tube that offers a capacity of seven shells.

But with the magazine mount on the barrel blocking a longer tube, I tried heating it with a propane torch to de-solder it but the temperature of the steel was going to warp the barrel so I decided to grind off the mount instead.

Then the longer tube could be installed without further conflict besides grinding off the magazine’s end cap flush and cold bluing it. But without the mounting tab on the end cap, I drilled and tapped a perpendicular screw to hold the magazine spring when compressed.

But then, there was nothing fastening the magazine tube to the shotgun. To solve that issue, I used two parts from the Rock Island Arsenal M5 shotgun to make the design work. The M5 had a heat shield that clamped to the magazine tube. It could hold the magazine tube to the barrel but it still did not provide enough rigidity, so I also added an M5 barrel band, which does provide the rigidity to their design. It would work here too.

For a retro-style fighting shotgun, it would need a sling. That meant adding sling mounts. Screwing in a sling swivel stud in the wood stock is easy. Coming up with a sling swivel point solution on the barrel is easy too. In this case, I went with the Choate brand barrel clamp with swivel stud. That added even more rigidity to keep the magazine tube fixed to the barrel. With three clamps, the magazine tube won’t work its way forward and fail.

With the cloth M1 Garand sling installed, the shotgun can now be slung and carried in the field.

Now it’s a dependable, retro-style fighting shotgun, Frankenstein’d together from the lowliest of parts. It’s a one-of-a-kind antique.